TIMELESS SERIES CASE STUDY

Role

Industrial Design - Product Development - Manufacturing - Project Management

CLIENT

SA Tasarim

TIMEFRAME

2012 - 2014

overview

In the world we live in, we are constantly reminded of time. First it was the Sun, then clocks, watches. Now it's cellphones, tablets, computers, tvs... Amazingly, there are lots of ways to learn the time, even from the washing machine... I wanted to design a watch without the 'watch' function. I also tried to find a new way to attach the strap to the case, a new way to adjust the length and make the strap and case interchangeable so people can customize their watch anytime. Remember, this was in 2012; customizable, interchangeable straps and cases were not as popular as today. Thank you Apple!

the problem

- We are constantly reminded of time

- It's hard to change the size, color of your watch strap (it's much easier now but in 2012 it wasn't)

- Watch straps are not as minimal as they should be

the solution

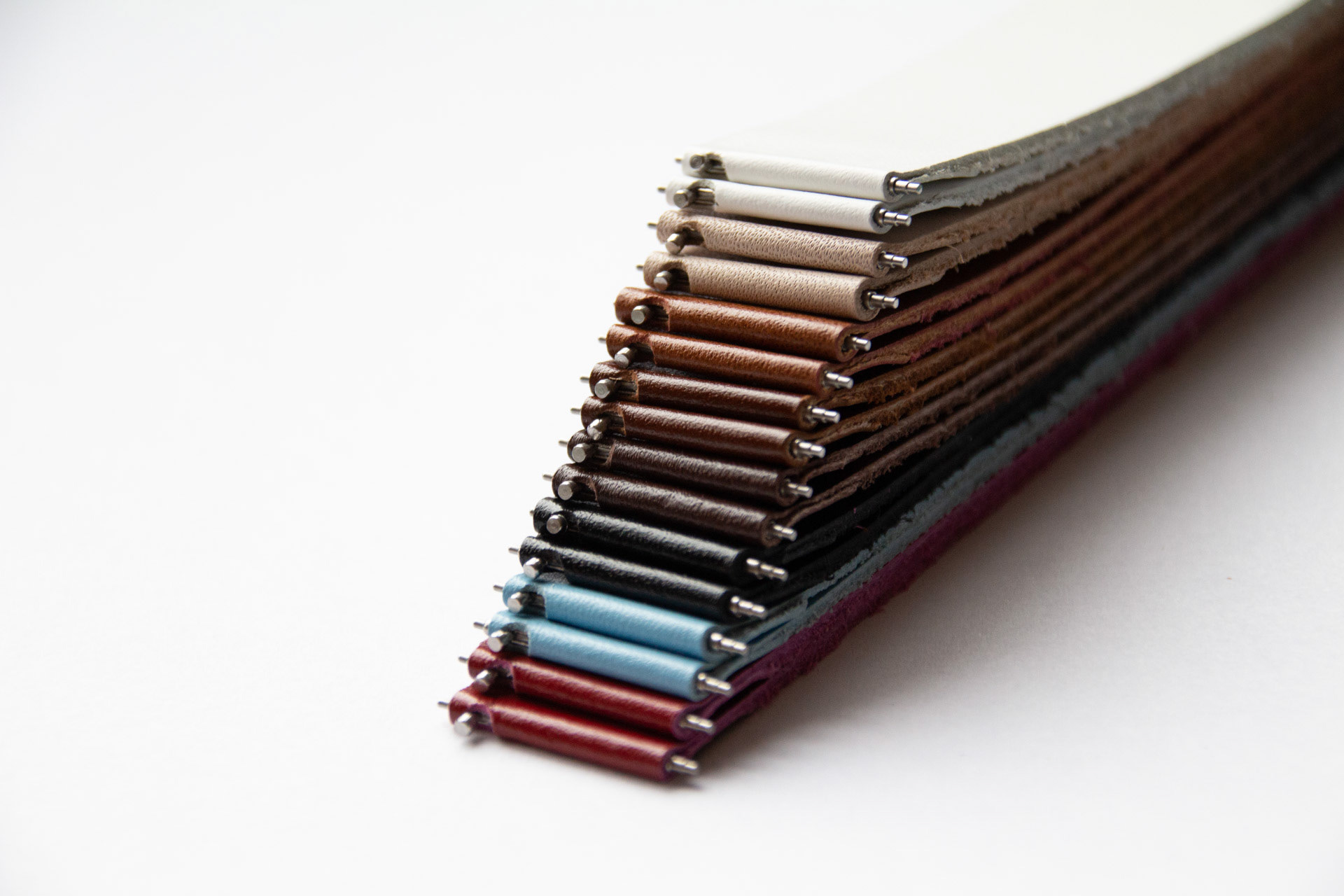

Timeless Series is a statement. 'f.ck time' says it all. Being able to change your strap or adjust the length in 5 seconds without any tools is an amazing feature. With 8 different cases (top and bottom) and 8 different straps you can make over 500 different combinations! It's made out of anodized aluminum and genuine leather so it will last a lifetime.

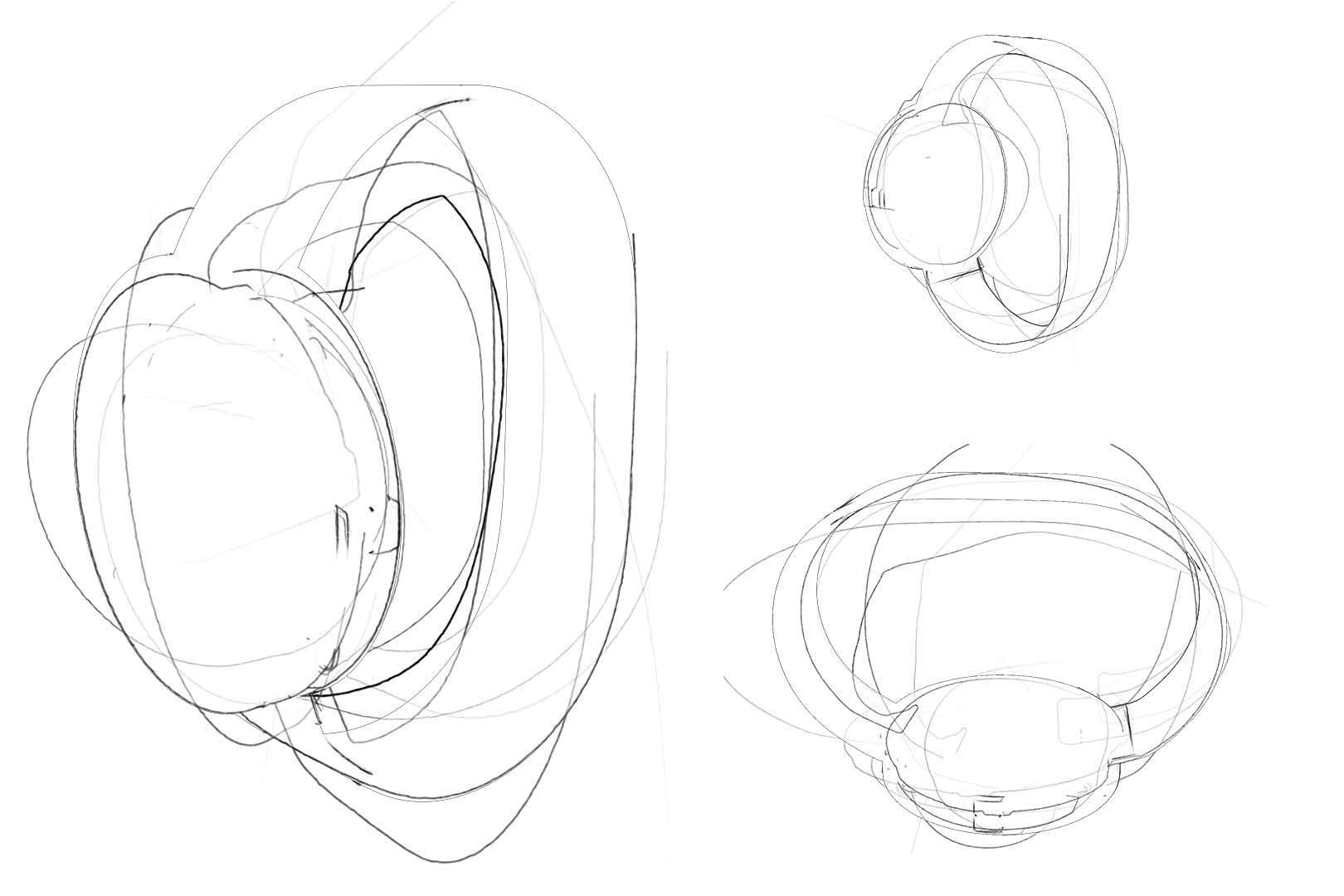

First sketches

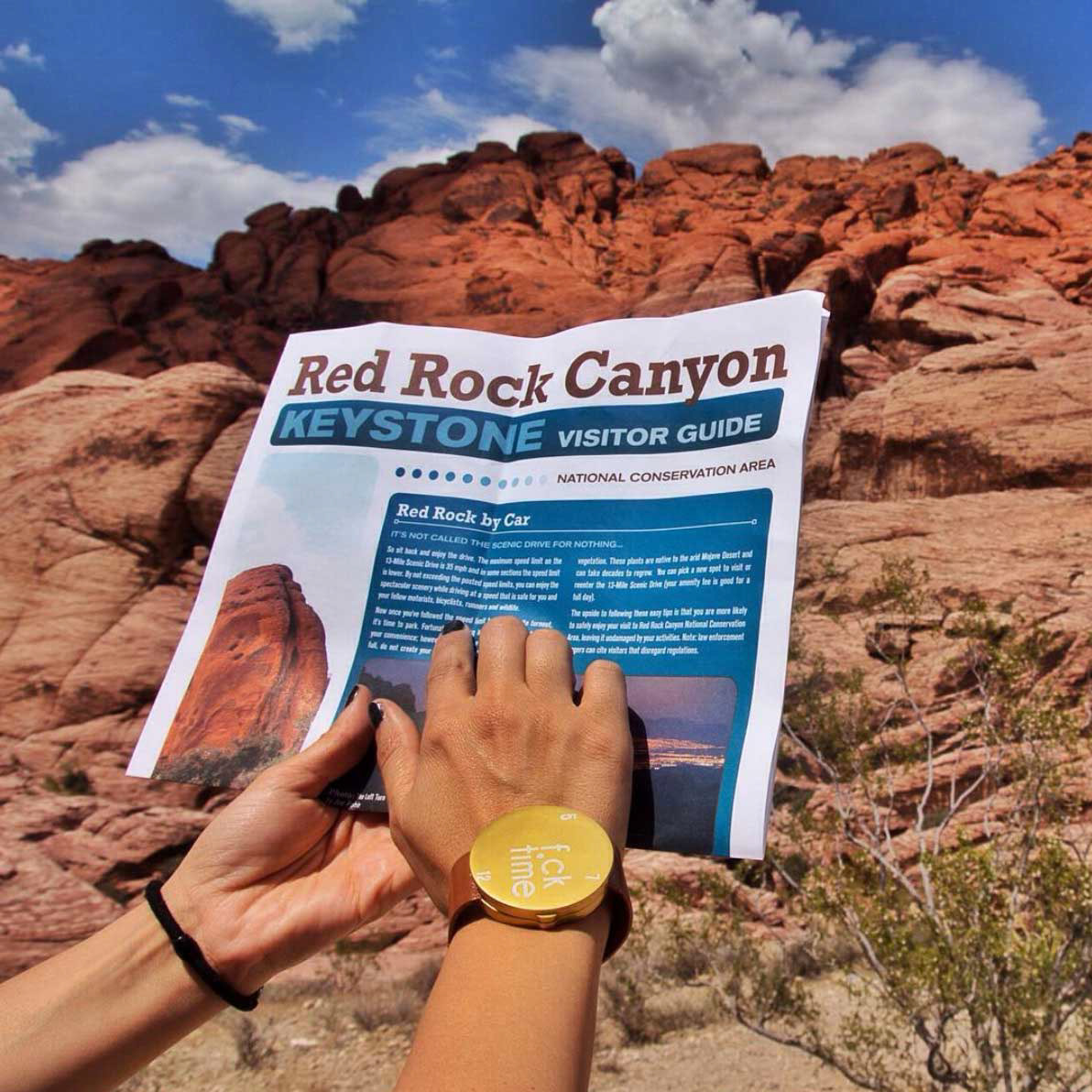

Final product

user research

I sent an online survey to hundreds of people to get an insight for their conception of time and behaviors of keeping time.

%96 said they own a watch

%72 said they wear their watch all the time

%92 said they use their phones to check time

%54 said they wear their watch as a fashion accessory

%86 said they would like to customize their watch whenever they want

the design process

WHAT THE F.CK IS THAT?

When I started working on this project, I remember wearing a pink foam prototype with a strap made out of paper taped on my wrist for days. The cuts I've had on my left wrist... Anyway, I didn't have a 3D printer or a laser machine back then, so I went to a shop and laser cut a prototype from black acrylic. Made a strap from some PU leather. The two cases clicked with 4 magnets and it was so satisfying. I was using it as a musical instrument all day, which must have been super annoying to people around me. I've worn the acrylic prototype for weeks, getting asked 'what the f.ck is that?' because it said 'f.ck time' on it. I'd open the case, adjust the strap in seconds and slap it on that person's wrist. They'd be amazed. That's when I knew this was something people would love.

HOW CUSTOMIZABLE ARE WE TALKING?

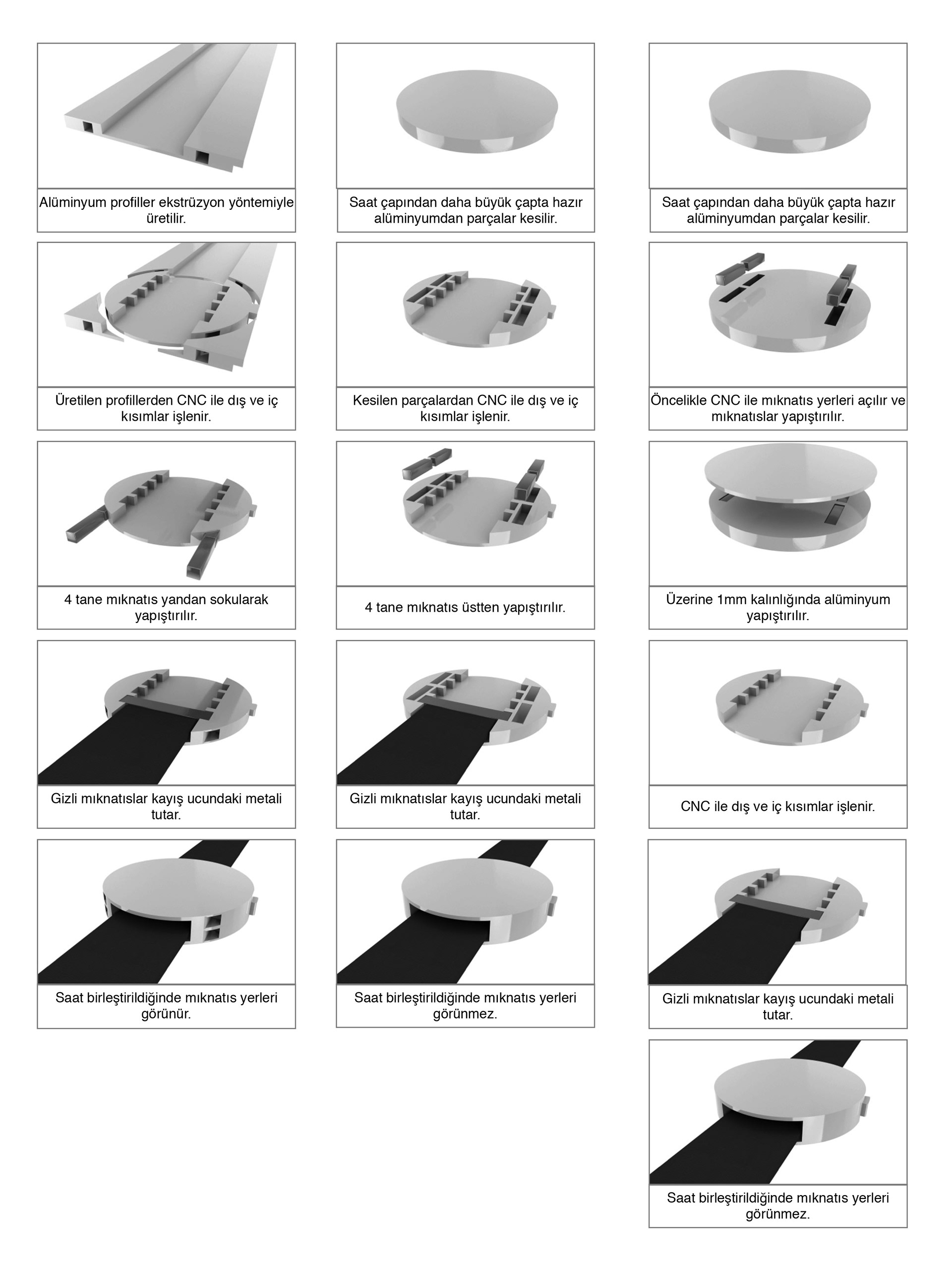

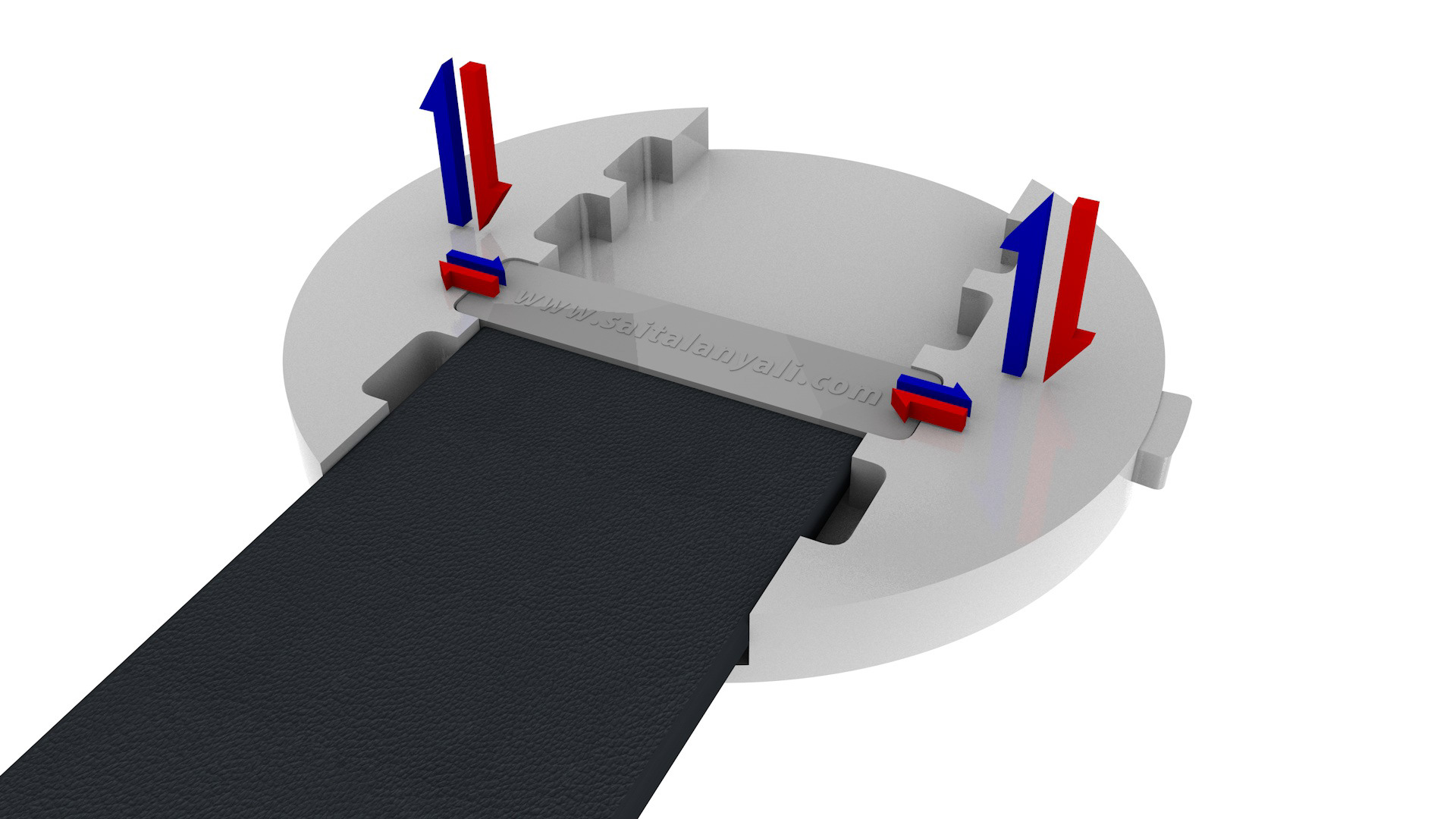

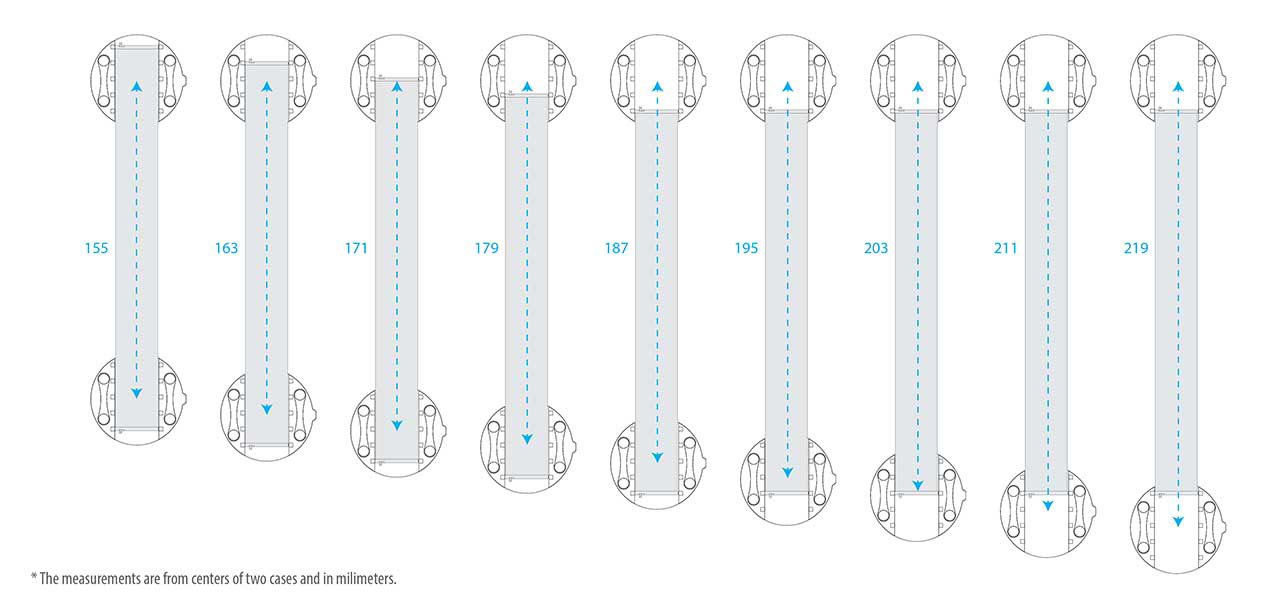

So what I wanted to do first was to hide the buckle of the strap, because I hated the feeling of it pressing on my wrist when I put my wrists on the table. But how do you adjust the length of the strap if you don't have a buckle? That's when I remembered I had all this space inside the case because I won't be putting a watch movement inside. What if I could adjust the strap inside the case and hide the parts? But to adjust the strap inside the case, you have to be able to reach inside the case. So I decided to split the case in half. This would help me in two ways; access to the inside and more customization options. The average human wrist is varied between 130-240mm. But majority of them are between 140-220mm. To adjust the strap inside the case, I had to find a way to attach them and make it very easy to adjust. My first idea was with magnets. I was gonna put some metal on both ends of the strap and they would fit inside the slots inside the case and hold there securely with magnets. I've tried a lot of prototypes and while it worked, I couldn't reach the lengths I wanted because the metal parts were so thick.

PIN ME UP SCOTTY!

I've seen quick release spring bar pins on some watches but they were not that popular back then. My idea was to make a slot on the case where one end of the strap would slide/hide, drill 5 holes on sides of that slot. The user would attach the strap to the cases with these quick release pins, change the strap or any of the cases or adjust the length of the strap.

MAGNETS!

Attaching two cases together was a whole other challenge. Like I've said above, I've tried a lot of prototypes with different magnet shapes, sizes, placements. I've tried some magnets where they would hold both the strap and the cases together. But like I've said, the metal parts at the end of the strap became so thick that I had to drop that idea. After I decided to use the quick release pins for the strap, all I needed from the magnets was to hold the two cases together. I've tried some sizes where you had to pry open two cases and some sizes where they would open with a small nudge. But after a few tries, I've found the perfect size and placement where the user can easily open the cases but it won't open by itself.

MATERIALS AND MANUFACTURING...

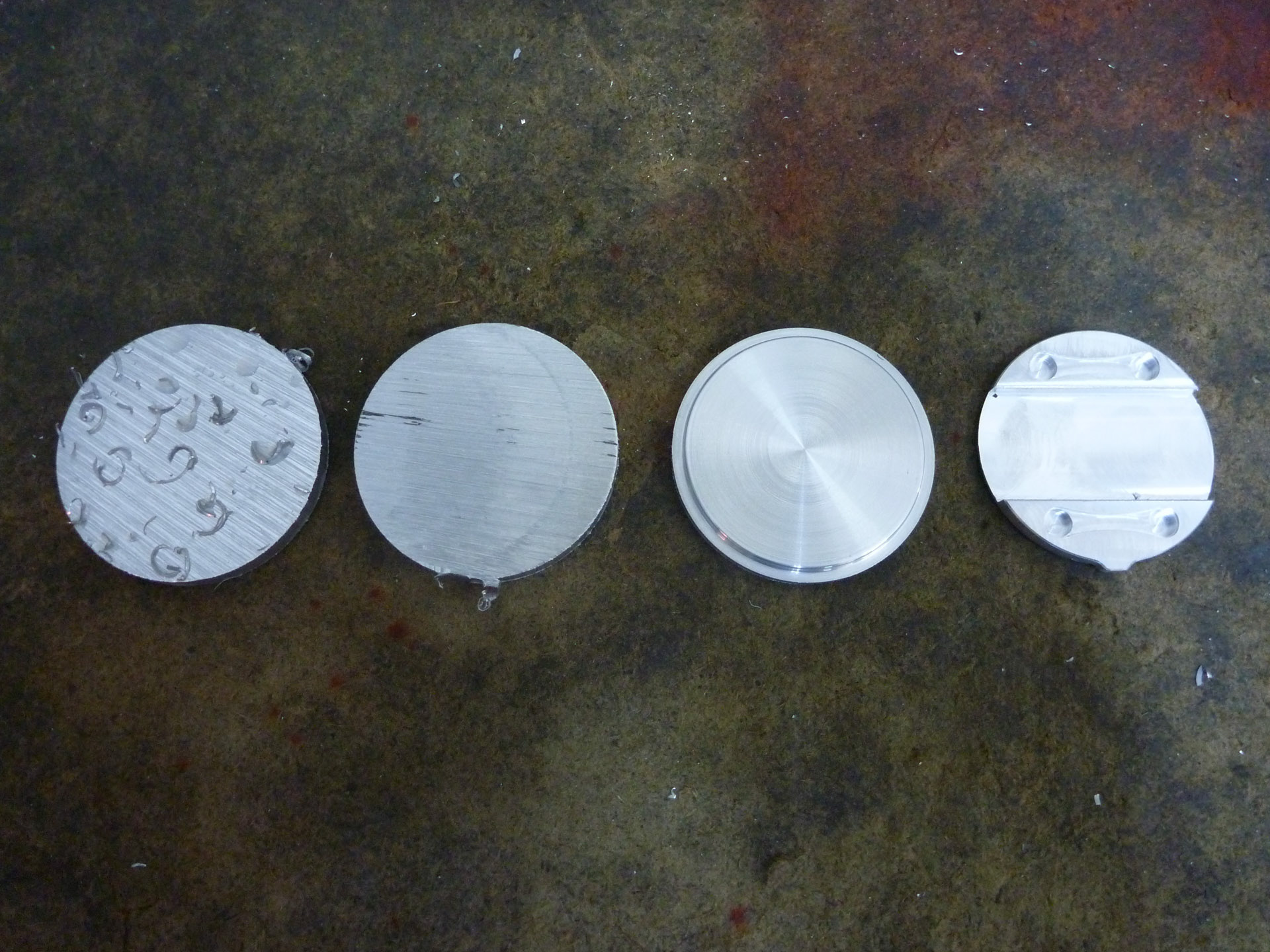

I was set on making the cases from aluminum from the start because the thinnest part of them where the strap laid on was 1,5mm and it had to be rigid. Material choice, easy! But the manufacturing was not. I have a friend whose uncle had a few cnc machines. Thanks to them we were able to try a lot of processes. In the end we chose 6061 aluminum rods, cut to certain thickness. Then we would lathe one side so we can hold it with a jig on the cnc mill. We would make the slot for the straps, holes for the magnets on the cnc mill. Then with another specifically angled jig we would drill the holes for the quick release pins. To cover the magnets, I designed an organic infinity symbol which also became the logo for the product and machined that over the magnet holes. We had to make a mold to cut these from very thin aluminum sheets.

HOW MUCH IS TOO MUCH CUSTOMIZATION?

To make the aluminum cases stronger and give them color, we chose to anodize them in 8 colors. To go with those cases, I chose 8 leather colors. The idea is a user can buy a few cases and straps so they can make different combinations depending on their look that day.

takeaways

In the end, this product reached out to a lot of customers worldwide, turned some heads and definitely was a conversation starter. This was my most technical design project and my first experience with a lot of manufacturing processes like 4 axis cnc milling, cnc lathe machining, die cutting and anodizing. I've learned a lot! I stopped selling these but even after 6 years, I still get messages of people wanting this product. Here are some photos of 'timeless series' from all around the world.